Oxy-Acetylene Welding and setup 101

So it is your first time getting to do some welding?! Here are the basics to get you started! The more you practice and learn the better you will get.

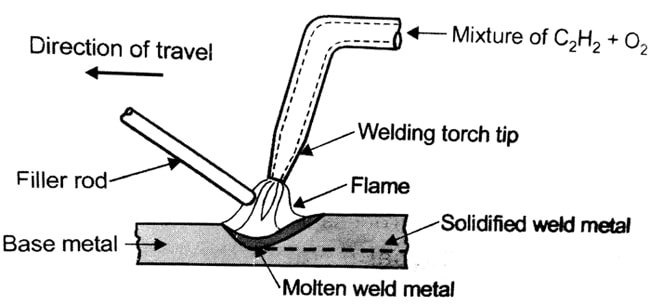

Oxy-Acetylene Equipment Procedures

A before O or up you go

Personal Safety Practice

Equipment Safety Practice

A before O or up you go

- Acetylene before Oxygen when lighting the torch

- Oxygen off before Acetylene when turning off the torch

Personal Safety Practice

- Wear appropriate clothing (closed toe leather shoes, natural fiber clothing,, and gloves)

- When performing a welding operation wear goggles with #5 shaded lenses.

- Make sure all combustible materials are away from the welding area.

- Know the location of the nearest fire extinguisher

- Keep work area clean

Equipment Safety Practice

- Store gas cylinders in an upright position… they should be secured to a wall or welding cart with chain so they cannot fall over.

- Never open the acetylene valve more than one complete revolution

- When moving or storing cylinders screw the valve covers in place

- Never oil or grease any fittings or threads on the oxy-acetylene setup

- Never allow the acetylene line pressure to exceed 15psi

- Discontinue use if the torch body becomes hot- notify instructor

- Always finish the shutdown procedure before leaving the work area

- If hoses light on fire shut off cylinder valves immediately

Setup For Use - use this guide as a checklist as you are setting up the torch!

Shutdown/ Storage Procedure

- Close both torch body valves and back off both regulators (thread out until it feels like there is no load on the screw)

- Standing to the side of the regulators (not standing in front of the gauge) open the main Acetylene cylinder valve half a turn (not more than one)

- Open the Acetylene knob (follow the red hose) on the torch to allow for acetylene pressure to be set.

- Turn the Acetylene regulator in until the line pressure reads 5-6 psi on the gauge. Close the acetylene knob on the torch.

- Open the main Oxygen cylinder valve all the way.

- Open the Oxygen knob (follow the green hose) on the torch to allow for oxygen pressure to be set.

- Turn the Oxygen regulator in until the line pressure reads 5-10 psi (or if using a cutting torch 5psi acetylene, 20 psi oxygen). Close Oxygen valve on torch handle

- Holding the torch body in one hand, and the torch tip facing away from yourself and others, open the acetylene knob/valve (counter-clockwise) on the torch just enough to feel the air blowing on your hand.

- Use a striker to light the torch.

- Adjust the acetylene valve so that the flame is slightly smoky. The black sooty stuff is carbon and can make a mess!

- Turn on the Oxygen knob/valve (green hose side) and adjust for a neutral flame. The little bright cone should have a slightly feather.

- Perform welding operation

- To turn off torch close the Oxygen knob/valve first, then the Acetylene. This will help purge the torch of gases

- Turn off the Acetylene gas first if there is an emergency and if you need the flame off right away. Quickly close the oxygen next.

Shutdown/ Storage Procedure

- With both the torch body needle valves closed, completely close the valves on the tops of the cylinders.

- With the cylinder valves closed, open the needle valves on the torch body and let the line pressure drop to zero (watch the line pressure and cylinder pressure gauges drop)

- Close both needle valves on the torch body and back out both regulators to the neutral position (no pressure being placed on internal diaphragm)

- Wrap up hoses and put away all accessories

- Clean up general work area

Easy 8 Step setup reminder

1. Open Acetylene Tank valve ½ turn counter clockwise

2. Open Acetylene valve on torch ¼ turn

3. Adjust Acetylene Regulator to between 5-7 psi depending on operation

4. Close Acetylene valve on torch

5. Open Oxygen Tank valve all the way counter clockwise

6. Open Oxygen valve on torch ¼ turn

7. Adjust Oxygen Regulator to around 10 psi depending on operation

8. Close Oxygen valve on torch

You are now ready to light the torch as listed in step 8 in the above section.

| metalwork_oxy-acetylene_setup_written_test.pdf | |

| File Size: | 139 kb |

| File Type: | |

| metalwork_oxy_acetytlene_torch_setup_2024_update.pdf | |

| File Size: | 126 kb |

| File Type: | |